16

2025

-

01

Medium frequency induction furnace pneumatic building machine

Before using a medium-frequency induction furnace, the furnace body needs to be built

Pneumatic Ramming Machine for Medium Frequency Furnace

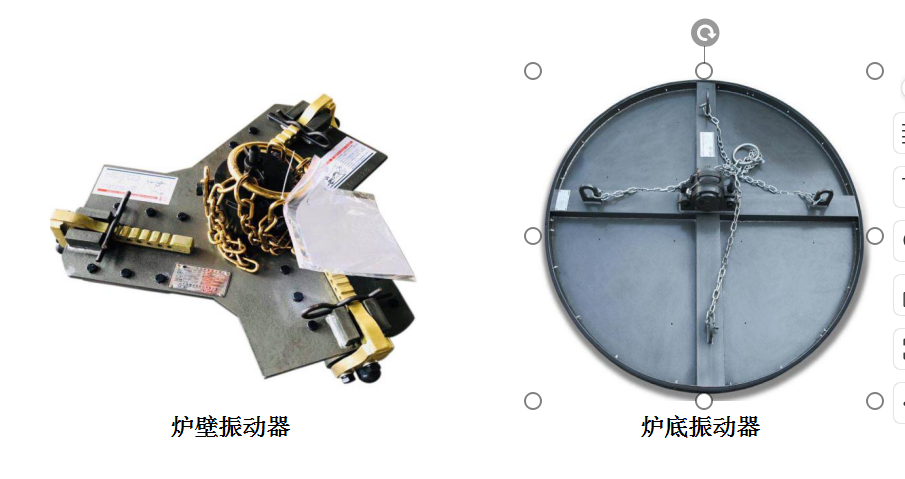

Before using a medium frequency induction furnace, the furnace body needs to be rammed, which is also known as ramming the lining. A ramming machine is required when ramming the lining of a medium frequency induction furnace. Ramming machines for medium frequency induction furnaces come in pneumatic and electric types.

A pneumatic ramming machine for medium frequency induction furnaces consists of a gas distributor, cylinder sleeve, pneumatic hammer head, length adjusting rod, and chain. It is mainly used for ramming dry lining materials in medium frequency induction furnaces. The pneumatic ramming machine for medium frequency induction furnaces utilizes the principle of the pneumatic hammer head striking the inner wall of the crucible in the medium frequency furnace, allowing the large and small particles of the lining material to fill the gaps, achieving a tight lining material effect.

1. The pneumatic ramming machine for medium frequency induction furnaces reduces manpower, shortens operation time, and lowers production costs.

When using a pneumatic ramming machine for medium frequency induction furnaces to ram the lining, one or two people can operate it. After the mixture is put into the crucible and the induction coil of the medium frequency induction furnace, the overhead crane is controlled to drive the pneumatic vibrator to move from bottom to top, reducing manpower and greatly shortening the operation time (ramming a 10T medium frequency melting furnace can be completed in just 1 hour).

2. The pneumatic ramming machine for medium frequency induction furnaces rams the inner wall of the crucible, making the ramming effect even and meticulous.

After the mixture is put into the medium frequency induction furnace pneumatic ramming machine, the pneumatic ramming machine rotates upward from the bottom of the wall, making the mixture ramming very uniform and preventing the crucible from tilting. The thickness of the rammed furnace wall is also uniform.

3. The pneumatic ramming machine for medium frequency induction furnaces performs one-time ramming, without foreign objects mixing in during ramming.

Because the mixture is put in for ramming at one time, the pneumatic vibrator of the medium frequency induction furnace can seal the charging port during internal ramming, so no foreign objects will mix in.

4. The sintering layer thickness of the ramming performed by the pneumatic ramming machine for medium frequency induction furnaces is uniform, maintaining the powder layer and ensuring safe operation.

The mixture vibrated by the pneumatic ramming machine for medium frequency induction furnaces is uniform and meticulous, and is less prone to crucible tilting during vibration. No foreign objects are mixed into the mixture, reducing local erosion caused by foreign objects, maintaining the average thickness of the sintering layer, and maintaining the powder layer, preventing accidents caused by the leakage of molten metal due to local erosion during operation (i.e., preventing furnace leakage).

5. The pneumatic ramming machine for medium frequency induction furnaces uses an internal ramming method, avoiding dust and other pollution.

6. The pneumatic ramming machine for medium frequency induction furnaces self-rotates when ramming the lining, and the vibration force is always maintained at 1800N, making the lining ramming uniform and firm.

This document is technical information or an article from the internet, for reference and learning only. Please inform us if there is any infringement.

Xi'an Aobang Technology Co., Ltd. is one of the earliest and largest manufacturers of medium frequency furnaces in China. Main products include medium frequency furnaces, melting furnaces, medium frequency electric furnaces, medium frequency melting furnaces, etc., induction heating equipment. Mainly used in casting melting, and heat treatment before forging, sintering, and bending forming, as well as induction heating fields such as quenching of mechanical parts. Secondly, it is used for melting or heating of steel, copper, aluminum, zinc, tin, gold and silver.

New energy-saving medium frequency furnaces and medium frequency electric furnaces have advantages such as fast melting, small footprint, easy temperature control, low pollution, and environmental protection. Ancient city welcomes guests, let's share the feelings of Aobang. 13891865812 Luo Zong More information please visit: http://www.aobangkeji.com

Medium frequency furnace --- Xi'an Aobang Technology Co., Ltd.

Previous article

Previous article

Latest developments

2025-01-16

Medium frequency induction furnace pneumatic building machine

Before using a medium-frequency induction furnace, the furnace body needs to be built

2025-01-14

Parameters of sensors and furnace materials

The induction coil uses oxygen-free copper cold-extruded copper tubes, and is optimized using