07

2025

-

01

Induction sensor for a heating furnace

The induction sensor of the medium-frequency induction heating furnace is the heart of the entire system. It consists of an induction coil, furnace frame, base, furnace mouth plate, bakelite plate, copper nozzle, hose clamp, cooling water circuit, copper screws, bakelite column, connecting row, furnace lining material, stainless steel, etc.

Induction Heater for Through-Heating Furnace

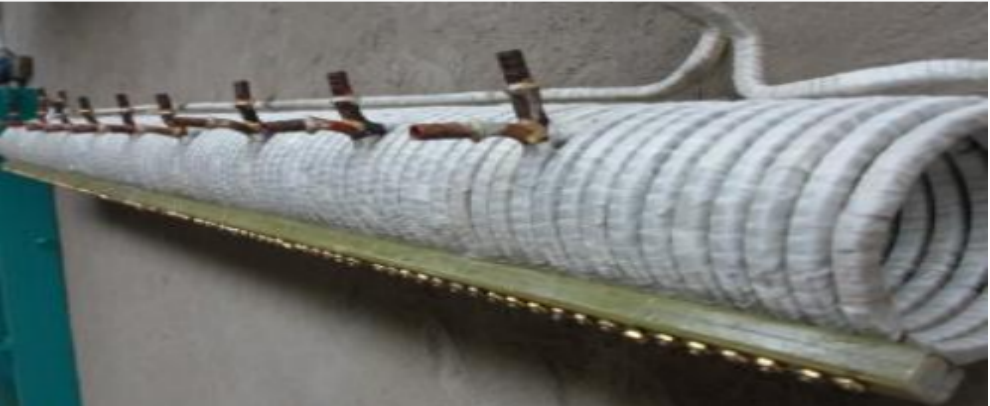

The induction heater for the through-heating furnace is the heart of the entire medium-frequency through-heating system. It consists of an induction coil, furnace frame, base, furnace mouth plate, bakelite plate, copper nozzle, hose clamp, cooling water circuit, copper screws, bakelite column, connecting row, furnace lining material, stainless steel, etc.

1. The induction heater for the through-heating furnace, or induction coil, is generally made by winding a rectangular copper tube with consistent metal flow and dense structure. The rectangular copper tube material uses T2 pure copper with a purity of 99.9%. In the design of the water circuit and coil grouping in the furnace head, the influence of the inherent length of the rectangular copper tube is considered. It is composed of coils with different numbers of turns and fixed and combined together with bakelite columns. In addition, each group of coils utilizes the welding of the copper tube and the combination of the power and water introduction parts, so that each group of induction coils is wound with a whole copper tube and no internal welds are needed.

2. The outer insulation of the induction heater for the through-heating furnace, or induction coil, adopts electrostatic spraying technology to spray a layer of high-strength insulating resin, with a temperature resistance exceeding 600 degrees and an insulation layer withstand voltage greater than 5000V.

3. The inside of the induction heater for the through-heating furnace uses a furnace lining method to isolate the heated metal material from the coil copper tube. The furnace lining protects the induction coil of the through-heating furnace. The furnace lining materials for the induction heater for the through-heating furnace, or induction coil, include the following two types:

a) The furnace lining uses a ramming cast furnace lining with high temperature resistance, high thermal strength, and good insulation performance. The refractory temperature of the induction heater is 1750℃. This structure makes the inductor have a long lifespan and high protection level for the induction coil. It is a new furnace construction technology and facilitates the installation and alignment of online temperature measurement, with high measurement accuracy. It is a commonly used method in current heating processes.

b) Using silicon carbide assembled molded furnace lining, wrapped with external insulation and heat preservation materials. Refractory temperature 1450℃, easy to replace. However, it is not conducive to temperature control of workpiece heating and is not suitable for heating large workpieces; it is easily broken.

4. The installation base, external dimensions, circuit, and water circuit connections of the induction heater for the through-heating furnace all consider interchangeability, making it easy to replace. The water circuit uses quick-connect fittings.

This document is technical data or an article from the Internet and is for reference and learning only. Please inform us if there is any infringement, and we will delete it.

Xi'an Aobang Technology Co., Ltd. is one of the earliest large-scale manufacturers of medium-frequency furnaces in China. Main products include medium-frequency furnaces, melting furnaces, medium-frequency electric furnaces, medium-frequency melting furnaces... and other induction heating equipment. Mainly used in casting melting, and heat treatment before forging, sintering, and bending forming, as well as induction heating fields such as quenching of mechanical parts. Secondly, it is used for melting or heating of steel, copper, aluminum, zinc, tin, gold, and silver.

New energy-saving medium-frequency furnaces and medium-frequency electric furnaces have the advantages of fast melting, small footprint, easy temperature control, low pollution, and environmental protection. The ancient city welcomes guests, and we share the feelings of Aobang. 13891865812 Mr. Luo For more information, please visit: http://www.aobangkeji.com

Heating furnace -- Xi'an Aobang Technology Co., Ltd.

Next article

Latest developments

2025-01-16

Medium frequency induction furnace pneumatic building machine

Before using a medium-frequency induction furnace, the furnace body needs to be built

2025-01-14

Parameters of sensors and furnace materials

The induction coil uses oxygen-free copper cold-extruded copper tubes, and is optimized using