Product Details

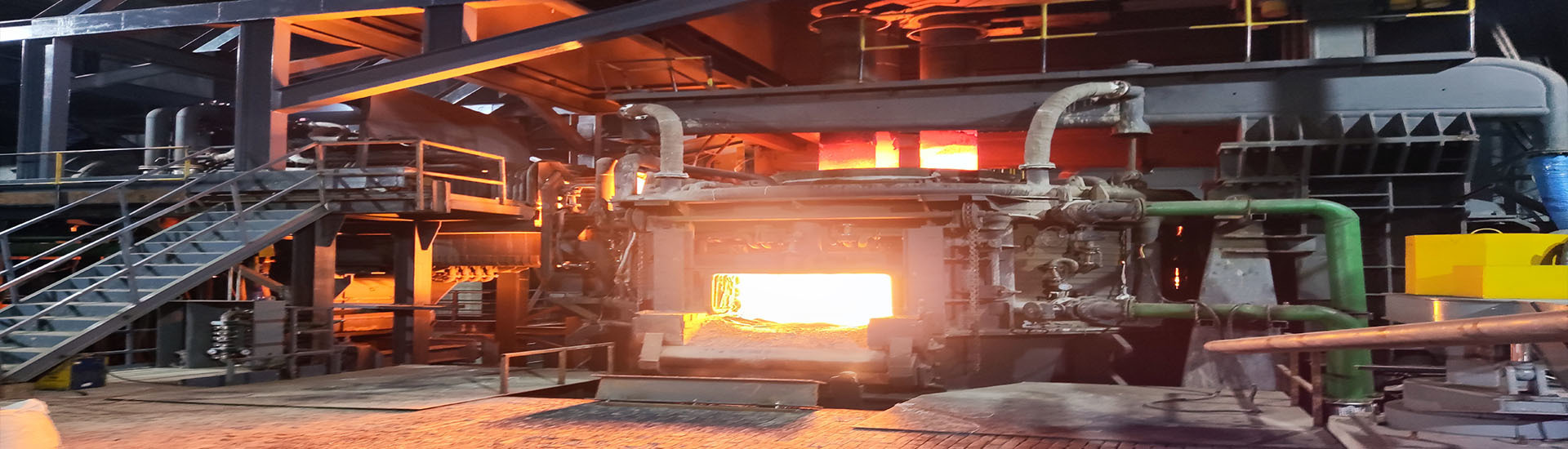

Induction coil

I. Induction Coil Manufacturing Process

Induction coil Made from a solid, durable, highly conductive TU1 oxygen-free copper tube seamlessly wound into a parallel structure with no joints in the middle; the copper tube boasts a wall thickness of ≥5mm. , the insulation process for the induction coil is: Coil sandblasting → Whole-part immersion varnishing (high-temperature insulating porcelain) → Vacuum baking varnish → Coil winding with insulation tapes (mica tape, fiberglass tape) → Insulation resin electrostatic spraying , the insulation grade exceeds Class H, and the insulation layer can withstand a voltage greater than 7000V.

The two adjacent copper tubes of the induction coil are strictly insulated from each other, and advanced segmented technology is employed to ensure seamless connections between the segments—eliminating any weld seams. After welding, the joints undergo two rigorous inspection processes to guarantee there’s no risk of water leakage: First, an ultrasonic non-destructive testing device is used to verify that the welds are free of internal defects; second, a 36-hour hydrostatic pressure test is conducted at 8 kg/cm², confirming complete leak-proof integrity.

Following this, the coil is coated with insulating varnish, forming a fully integrated structure that is then firmly compressed by the upper and lower steel frameworks within the furnace body. This results in a robust, deformation-free assembly.

The number of coil turns is carefully designed according to relevant parameters to achieve optimal electrical efficiency. Additionally, the coil is supplied with cooling water through multiple independent water circuits, ensuring even distribution. At the outlet end, several water temperature sensors are installed, each corresponding to its respective water circuit, for precise monitoring.

The induction coil is secured by a series of bolts welded onto its outer circumference, along with bakelite posts. The bakelite posts are designed with countersunk holes during manufacturing, and all bolts are tightened using countersunk heads to maximize insulation strength. After the coil is fixed, the pitch error between adjacent turns does not exceed 2 mm. Additionally, silicone gaskets are installed between each coil turn and the corresponding screw to prevent arcing, while the thermal expansion and contraction between the bakelite strips and the coil serve as an effective buffer.

Faraday short-circuit rings are installed at the upper and lower sections of the induction coil to guide and concentrate the induced magnetic field precisely into the melting area, preventing heat buildup in the furnace cross-section while eliminating overheating of external metal structures. Additionally, stainless steel water-cooling rings are positioned at both the top and bottom of the induction coil, ensuring uniform axial heating of the furnace lining material and thereby extending the service life of the lining.

II. Technical Features of Induction Coils

Serial Number

|

Features

|

Advantages

|

Note

|

1

|

Coil Structure

|

Electricity utilization efficiency is maximized, resulting in significant energy-saving effects.

|

|

2

|

Coil material |

The wall thickness of TU1 copper tubing shall not be less than 5 mm. |

|

3

|

Insulation Process

|

The insulation rating has been enhanced and is unaffected by external moisture.

|

|

4

|

Coil Welding Inspection Procedure |

Industry-first non-destructive flaw detection and extended high-pressure air-tightness testing ensure leak-free welded copper pipes. |

|

5

|

Integrated Molding Parallel Coil Technology

|

The coil effectively withstands forces acting around its entire circumference, preventing deformation while ensuring the electromagnetic beam generated by the coil remains uniform and stable, thus preventing coil winding-back and suppressing noise and vibration.

|

|

6

|

Faraday Short-Circuit Ring Design

|

Fully absorb the leakage flux from both ends

|

|

7

|

Stainless Steel Water-Cooling Coil Design

|

The furnace lining heats evenly, extending its service life.

|

|

8

|

Water Temperature Detection Device

|

Water temperature interlock alarm triggers automatic shutdown.

|

|

9

|

Insulation Class

|

H-Class |

|

10

|

Insulation Layer Voltage Resistance Rating |

≥7000V |

|

Xi'an Aobang Technology Co., Ltd. is one of the early domestic manufacturers that have scaled up production of medium-frequency furnaces. Its main products include a full range of induction heating equipment, such as medium-frequency power supplies, IGBT power supplies, melting furnaces, and heating furnaces. For many years Focusing on Induction heating equipment Research and Development & Manufacturing Based in the ancient city of Xi'an, Aobang Technology is committed to "driving innovation in industrial heating through technology." Leveraging its core technologies accumulated from early large-scale production, the company provides customers with end-to-end services—ranging from equipment selection and installation/commissioning to process optimization.

The ancient city welcomes guests, together sharing the bonds of Aobang. We look forward to collaborating with more industry partners to push the boundaries of induction heating technology innovation. 13891865812 Mr. Luo

Previous

Next

Previous

Next

I want to consult