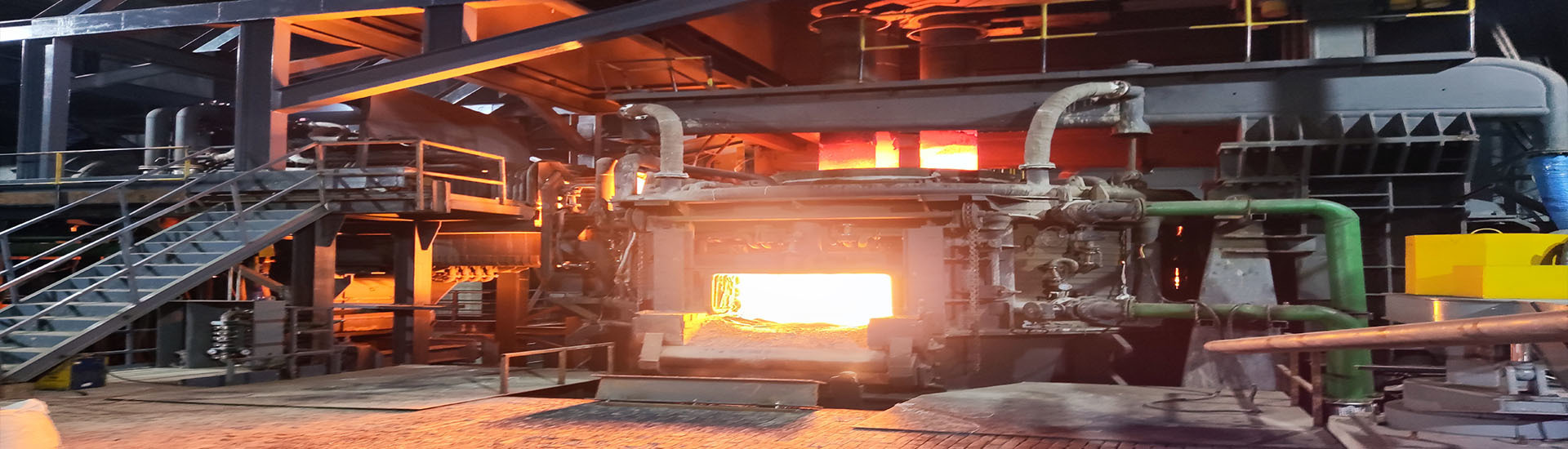

Medium-Frequency Melting Furnace

Medium-Frequency Melting Furnace

Keyword:

You can send us an email:1620573240@qq.com

Online messageProduct Details

1. Steel-cased furnace body

The furnace structure has been optimized to enhance both its strength and safety during operation. This includes refining the connection method for the water-cooled cables, as well as incorporating a support mechanism that eliminates the mutual forces between the water-cooled cables and the coil during the furnace's rotation. Such improvements not only extend the lifespan of the water-cooled cables but also ensure the stability of the coil throughout the process.

2. Drop-proof device

During the tilting process, a large pit often forms behind the medium-frequency furnace. To prevent workers from accidentally falling, our company equips each medium-frequency furnace set with a fall-protection device, ensuring safety and minimizing the risk of accidents during furnace tilting.

3. Remote Console

This device is placed on the furnace platform, where operators perform actions such as starting, stopping, and resetting the power supply. The PLC and human-machine interface together form a user-friendly melting manager, offering functions including automatic furnace baking, cold furnace startup, fault diagnosis, display and storage of error information, water system monitoring, real-time operational data visualization, and system status display, among others.

4. Induction coil

Constructed from robust, durable, and highly conductive T2 copper tubing. Multiple meticulous manufacturing processes ensure precision—resulting in a single-step winding and shaping process, with arc-shaped insulation spacers between turns to maintain uniform coil spacing while also promoting efficient moisture evacuation. After sandblasting for precise coil shaping, the exterior is tightly wrapped with insulating material and then fully encapsulated in a single, seamless casting. This advanced method delivers superior strength and durability compared to the conventional application of adhesive paste, eliminating gaps over time and significantly reducing the risk of furnace leakage or coil failure—thereby extending the lifespan of the coil considerably.

Equipped with molded insulation panels and short-circuit rings, the composite leak-proof probes installed at the furnace top and bottom are both safe and reliable. They automatically cut off the power supply and trigger an alarm when molten iron begins to penetrate or is about to breach the refractory materials and coils. These composite leak-proof probes serve as a critical component of the entire furnace leakage protection system, while also ensuring that the molten iron remains grounded—thus safeguarding the safety of operating personnel.

5. Cyclone-Type Dust-Removal Furnace Cover

During the smelting process, electric furnaces generate significant amounts of smoke, dust, and harmful gases such as CO and fluorides, posing a serious threat to air quality. These emissions make electric furnaces one of the major sources of atmospheric pollution. Additionally, large quantities of airborne dust are released, severely contaminating the working environment for车间 workers. To address these challenges—ensuring that the system doesn’t interfere with normal operations while effectively capturing harmful gases emitted from the furnace, and simultaneously recovering dust that holds substantial economic value—weekly, our company’s technical team leveraged years of expertise in designing and manufacturing melting equipment, combined with extensive experience in developing complementary dust collection systems. Through meticulous multi-stage design and rigorous testing, we’ve finally crafted a highly effective yet simple and cost-efficient dust removal solution: the cyclone-type dust-collecting furnace cover.

Main Parameters (Selection Guide) for the GW Series Intermediate-Frequency Coreless Induction Melting Furnace

Rated Capacity (T) | Rated Power (kw) | Rated frequency (Hz) | Rated Operating Voltage (V) | Input voltage | Steel Melting (1550°C) | Transformer capacity | |

Melting rate (T/H) | Power consumption (kW·h·t) | (KVA) | |||||

0.5 | 500 |

1000 |

750/2400 |

3-phase 380V 660V/50Hz Or 60 Hz | 0.8 | 600 | 600 |

1 | 500 | 0.8 | 600 | 600 | |||

1 | 1000 | 1.7 | 580 | 1100 | |||

1.5 | 1000 | 1.7 | 580 | 1100 | |||

2 | 1250 |

500 |

2400 |

6-phase 660V 50 Hz or 60 Hz | 2.1 | 580 | 1400 |

2 | 1500 | 2.5 | 580 | 1650 | |||

2 | 2000 | 3.4 | 580 | 2200 | |||

3 | 2000 | 3.6 | 550 | 2200 | |||

3 | 2500 | 4.5 | 550 | 2800 | |||

5 | 2500 |

300 |

2600 |

12-phase 660V / 50Hz or 60Hz | 4.5 | 550 | 2800 |

5 | 3000 | 5.4 | 550 | 3300 | |||

5 | 3500 | 6.3 | 550 | 3850 | |||

8 | 5000 | 9.4 | 530 | 5500 | |||

8 | 6000 | 11.3 | 530 | 7000 | |||

10 | 6000 | 11.3 | 530 | 7000 | |||

10 | 8000 | 15.0 | 530 | 9000 | |||

12 | 8000 | 15.0 | 520 | 9000 | |||

15 | 10000 | 18.8 | 520 | 11000 | |||

20 | 12000 | 22.6 | 520 | 14000 | |||

Medium-Frequency Melting Furnace

In the modern metalworking industry, medium-frequency melting furnaces play a crucial and indispensable role as highly efficient, energy-saving melting equipment. They are not only widely used in the melting of steel and non-ferrous metals but also demonstrate significant potential across fields such as casting, forging, and even scrap metal recycling. This article will provide a detailed overview of medium-frequency melting furnaces, covering their working principles, equipment structure, technical features, application areas, and emerging development trends.

1. The Working Principle of Medium-Frequency Melting Furnaces

The working principle of an intermediate-frequency melting furnace is based on electromagnetic induction heating technology. When alternating current passes through the induction coil, it generates a varying magnetic field around it. When this oscillating magnetic field interacts with the metal workpiece placed inside, eddy currents are induced within the metal itself. As these eddy currents flow through the metal, they encounter resistance, producing significant heat that ultimately melts the metal. The intermediate-frequency melting furnace typically operates at current frequencies ranging from 1,000 Hz to 10,000 Hz—this specific frequency range enhances the efficiency of electromagnetic induction heating while ensuring more uniform heating throughout the material.

2. Equipment Structure

The medium-frequency melting furnace primarily consists of several major components, including the power system, induction coil, furnace body, cooling system, and control system.

1. Power System: Provides medium-frequency AC power and typically includes components such as rectifiers, filters, inverters, and load-matching networks. The performance of the power system directly affects the heating efficiency and stability of the melting furnace.

2. Induction coil: This is the core component of electromagnetic induction heating, typically constructed by winding copper tubing. Coolant flows through its interior to prevent overheating. The design of the induction coil directly influences both heating efficiency and the uniformity of the molten metal pool.

3. Furnace Body: Designed to hold the metal intended for melting, typically constructed from refractory materials that can withstand high temperatures while maintaining the stability of the molten pool. The furnace body’s design must account for the material’s thermal expansion properties, thermal shock resistance, and erosion durability.

4. Cooling System: Primarily used to cool parts of the induction coil and power system components, ensuring the equipment operates reliably over the long term. The cooling medium is typically water or oil.

5. Control System: Enables automated control of the melting process, including functions such as temperature control, power adjustment, and fault diagnosis. Modern medium-frequency melting furnaces typically utilize PLC or DCS control systems, significantly enhancing operational convenience and ensuring greater stability in the melting process.

3. Technical Features

Compared to traditional resistance furnaces, oil-fired furnaces, and others, medium-frequency melting furnaces have the following notable features:

Highly efficient and energy-saving: Electromagnetic induction heating acts directly on the metal’s interior, delivering high thermal efficiency with minimal energy loss.

Even heating: Induction heating ensures a uniform distribution of eddy currents within the metal, resulting in consistent heat distribution and significantly enhancing the performance of metallic materials.

Easy to control: By adjusting the power frequency and output, the heating speed and temperature can be precisely managed to meet the requirements of various melting processes.

Eco-friendly cleaning: No fuel combustion is required, significantly reducing harmful gas emissions and aligning with the demands of modern green manufacturing.

Highly flexible: Suitable for melting a variety of metal materials, with adjustable melting capacity and excellent adaptability.

4. Application Areas

Medium-frequency melting furnaces are widely used in the metalworking industry, including but not limited to:

Steel smelting: Used for hot metal preheating, alloy steel melting, and more.

Non-ferrous metal smelting: The melting and alloy preparation of metals such as copper, aluminum, zinc, magnesium, and more.

Foundry Industry: Providing high-quality molten metal for casting.

Forging industry: Preheating and melting metal billets to meet the requirements of the forging process.

Scrap Metal Recycling: Efficiently process used metals to enable the circular use of resources.

5. Development Trends

With the advent of Industry 4.0, medium-frequency melting furnaces are rapidly advancing toward intelligent and automated operations. Looking ahead, these furnaces will place greater emphasis on improving energy efficiency, incorporating cutting-edge control algorithms to achieve precise management of the melting process. At the same time, miniaturization and modular design will also become key trends, enabling the equipment to better meet the diverse needs and scale requirements of users. Moreover, the development and widespread adoption of eco-friendly, energy-efficient medium-frequency melting furnaces will play a vital role in helping the metal processing industry embrace sustainable, green growth.

In summary, medium-frequency melting furnaces play an indispensable role in the metalworking industry thanks to their efficient, energy-saving, and environmentally friendly technological features. As technology continues to advance and their application areas expand, medium-frequency melting furnaces are poised for even broader prospects of growth and development.

Xi'an Aobang Technology Co., Ltd. is one of the early domestic manufacturers that scaled up production of medium-frequency furnaces. Its main products include a full range of induction heating equipment, such as medium-frequency power supplies, IGBT power supplies, melting furnaces, and heating furnaces. Focusing on Induction heating equipment R&D and Manufacturing Based in the ancient city of Xi'an, Aobang Technology is driven by the mission to "revolutionize industrial heating through technology." Leveraging its core technologies—gained from early large-scale production—we offer customers a full-cycle service that spans equipment selection, installation and commissioning, to process optimization.

Ancient city welcomes guests, together sharing the bonds of Aobang. Looking forward to collaborating with more industry partners to push the boundaries of induction heating technology innovation. 13891865812 Mr. Luo

Previous

Next

Previous

Next

I want to consult