Product Details

Plate Heat Exchanger

The structural principle of plate heat exchangers:

A plate heat exchanger is primarily composed of a series of metal plates stacked together, with multiple independent flow channels formed between the plates via sealing gaskets. Each plate features a corrugated shape—this design not only maximizes the heat transfer area but also enhances turbulent flow of fluids between the plates, significantly boosting thermal efficiency. Cold and hot fluids flow separately through these channels, exchanging heat via thermal conduction across the plates.

The core components of a plate heat exchanger are the plates and sealing gaskets. The plates are typically made from corrosion-resistant materials such as stainless steel, titanium alloy, or nickel alloy, ensuring the equipment maintains reliable performance even under harsh operating conditions. Meanwhile, the sealing gaskets play a critical role in preventing fluid leakage, and their material and shape must be carefully selected based on the characteristics of the working medium as well as the pressure and temperature conditions.

Working characteristics of plate heat exchangers:

High-efficiency heat transfer: The corrugated plate design of plate heat exchangers significantly increases the heat transfer area, while turbulent flow enhances rapid heat exchange, resulting in far superior efficiency compared to conventional shell-and-tube heat exchangers.

Compact design: Thanks to the way the plates are stacked, plate heat exchangers are more compact in size, occupy a smaller footprint, and are easier to install and maintain.

High flexibility: By adding or removing plate numbers, the heat transfer area can be easily adjusted to meet varying heat exchange demands. Additionally, different flow channel layouts and plate configurations can be designed according to process requirements, ensuring optimal performance under specific heat exchange conditions.

Wide range of applicability: Plate heat exchangers can handle a variety of media, including steam, liquids, gases, and even fluids containing solid particles, making them suitable for diverse operating conditions such as high temperature, high pressure, low temperature, and low pressure.

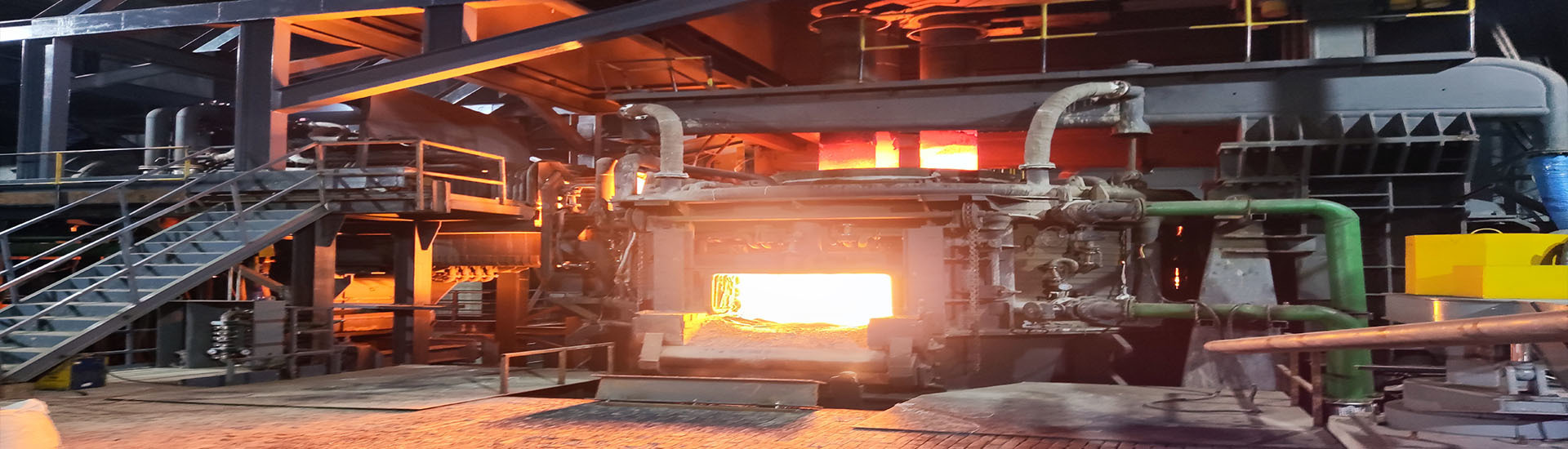

Xi'an Aobang Technology Co., Ltd. is one of the early domestic manufacturers that have scaled up production of medium-frequency furnaces. Its main products include medium-frequency power supplies, IGBT A full range of induction heating equipment, including power supplies, melting furnaces, and heating furnaces. Long-term Focusing on Induction heating equipment Research and Development & Manufacturing Based in the ancient city of Xi'an, Aobang Technology is committed to "driving innovation in industrial heating through technology." Leveraging its core technologies accumulated from early large-scale production, the company provides customers with end-to-end services—ranging from equipment selection and installation/commissioning to process optimization.

The ancient city welcomes guests, together sharing the bonds of Aobang. We look forward to collaborating with more industry partners to push the boundaries of induction heating technology innovation. 13891865812 Mr. Luo

Previous

Previous

I want to consult