Closed-circuit cooling tower

Closed-circuit cooling tower

Category:

Keyword:

You can send us an email:1620573240@qq.com

Online messageProduct Details

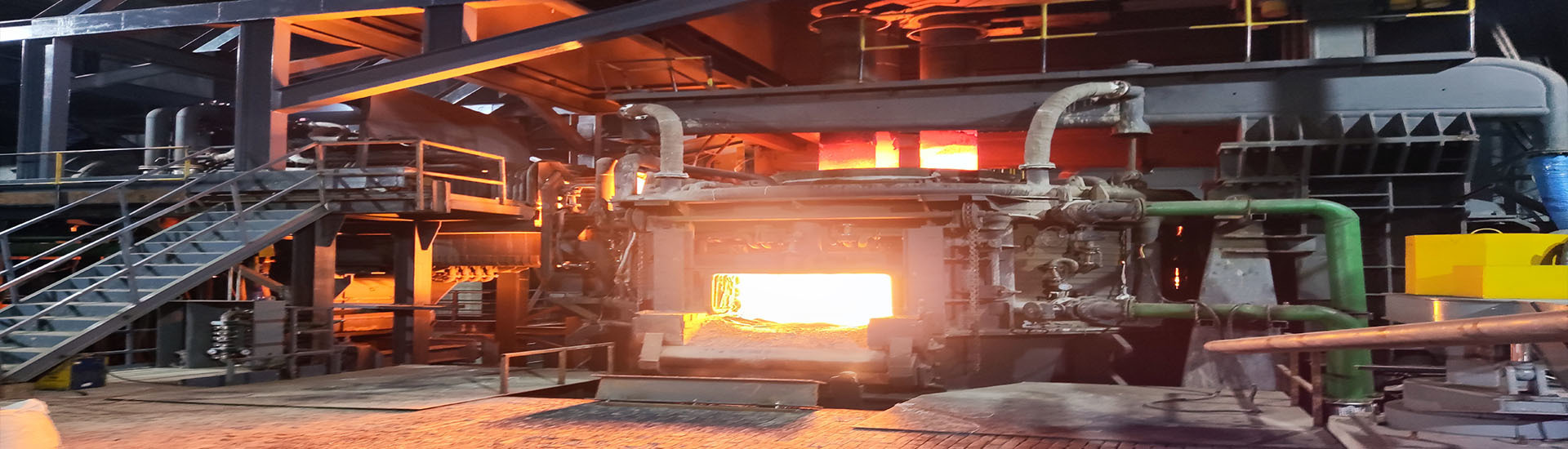

Closed-circuit cooling tower

In industrial production and large-scale commercial facilities, cooling systems are an indispensable and critical component that ensures the smooth operation of machinery and equipment. Among these, closed-circuit cooling towers—known for their efficiency and energy-saving benefits—have garnered significant attention and widespread adoption in recent years. This article will provide a detailed introduction to closed-circuit cooling towers, covering their fundamental principles, structural features, practical advantages, as well as maintenance and upkeep considerations.

I. The Basic Principle of Closed-Circuit Cooling Towers

As the name suggests, the core feature of a closed cooling tower is that its cooling process takes place within a relatively closed system. Compared to traditional open cooling towers, the working medium in a closed cooling tower—typically cooling water—does not come into direct contact with outdoor air. Instead, it exchanges heat with air via a heat exchanger, effectively preventing issues such as water contamination and evaporative water loss.

Here's how it works: Hot water flows out of the machinery and enters the heat-exchange coil inside the closed cooling tower. At the same time, ambient air is drawn into the tower by a fan and passes through a specially designed packing layer, which significantly increases the contact area between the air and the outer surface of the heat-exchange coil, thereby enhancing the efficiency of heat transfer. As the air moves past the coil, it absorbs heat from the hot water inside, then exits the tower. Meanwhile, the hot water loses its thermal energy as it cools down and eventually flows back into the machinery for continued use.

II. Structural Features

The closed cooling tower features a compact structural design and consists primarily of components such as a heat exchanger, fan, packing layer, water pump, water tank, and control system.

Heat exchangers are typically made from high-efficiency heat-transfer materials, such as copper or stainless steel tubes, which offer excellent thermal conductivity and corrosion resistance.

The fan is responsible for drawing outside air into the tower and ensuring that the air flows through the packing layer and heat exchange coils, facilitating efficient heat transfer. The selection of the fan must be carefully matched to the cooling tower's size and its specific heat exchange requirements.

The packing layer is positioned above the heat exchange coil to increase the contact area between air and the heat transfer surface, thereby enhancing thermal exchange efficiency. The packing material is typically made of plastic or metal, offering excellent air permeability and corrosion resistance.

The water pump is responsible for delivering hot water from the machinery to the heat exchanger for cooling, and then returning the cooled water back to the equipment.

Water tank: Used to store cooling water, ensuring a stable water supply during system operation.

Control System: Enables automatic control of key components such as fans and pumps, ensuring the cooling tower operates safely and efficiently.

III. Application Advantages

Excellent water-saving performance: Thanks to the closed-loop system used in closed-type cooling towers, evaporative water loss is significantly reduced. Compared to open-type cooling towers, the water-saving rate can reach up to 90% That's all.

Water quality protection: The closed-loop system prevents direct contact between cooling water and external air, effectively avoiding water contamination and scaling issues, thereby extending the system's service life.

Energy Conservation and Emission Reduction: The closed-loop cooling tower employs advanced heat exchange technology and variable-speed fan control, enabling it to adjust operating power according to the actual load, thereby achieving energy savings and emission reductions.

Wide range of applications: Suitable for various industrial production and commercial facilities requiring cooling, such as power plants, chemical plants, data centers, hospitals, and more.

Xi'an Aobang Technology Co., Ltd. is one of the early domestic manufacturers that have scaled up production of medium-frequency furnaces. Its main products include a full range of induction heating equipment, such as medium-frequency power supplies, IGBT power supplies, melting furnaces, and heating furnaces. For many years Focusing on Induction heating equipment Research and Development & Manufacturing Based in the ancient city of Xi'an, Aobang Technology is committed to "driving innovation in industrial heating through technology." Leveraging its core technologies accumulated from early large-scale production, the company provides customers with end-to-end services—ranging from equipment selection and installation/commissioning to process optimization.

The ancient city welcomes guests, together sharing the bonds of Aobang. We look forward to collaborating with more industry partners to push the boundaries of induction heating technology innovation. 13891865812 Mr. Luo

Previous

Next

Previous

Next

I want to consult