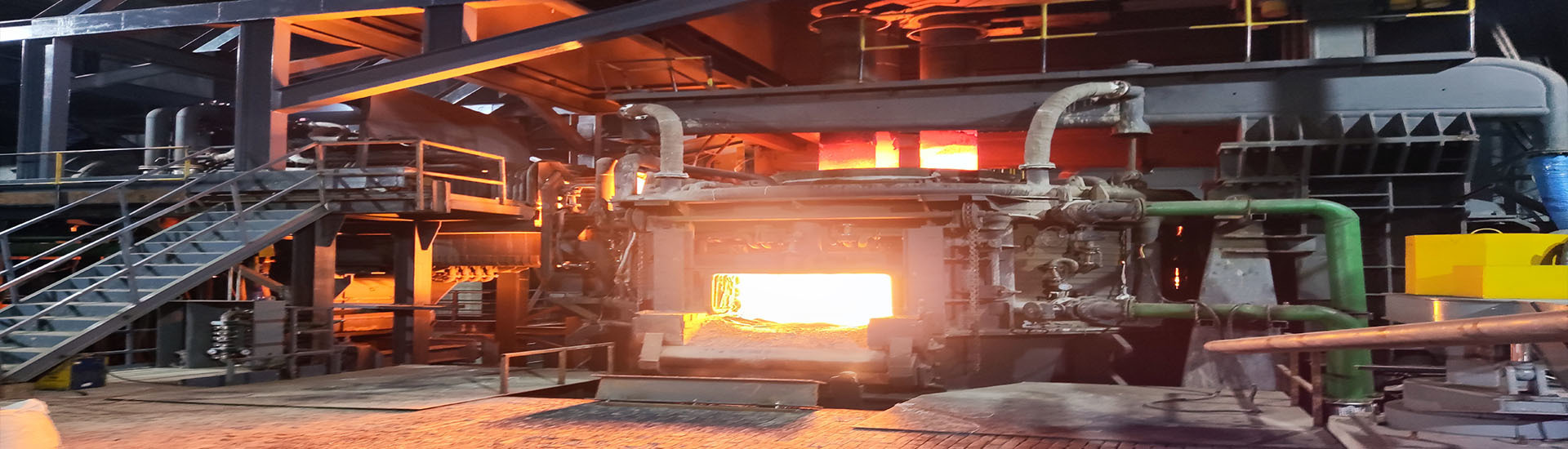

Induction heating equipment

Induction heating equipment

Keyword:

You can send us an email:1620573240@qq.com

Online messageProduct Details

The Technical Principles and Features of Induction Heating

Electromagnetic Induction and Eddy Current Heating

Induction heating utilizes the thermal effect generated when induced currents (eddy currents) are produced in a conductor placed within an alternating electromagnetic field, causing the conductor itself to heat up. Depending on the specific heating process requirements, induction heating systems employ power supplies with frequencies ranging from industrial frequency (50–60 Hz), to medium frequency (60–10,000 Hz), and high frequency (above 10,000 Hz). Importantly, the object being heated must be a conductor. Induction heating allows direct internal heat generation within the material, resulting in high thermal efficiency, rapid temperature rise, and the ability to achieve either uniform whole-part heating or localized heating—including surface heating—precisely as needed.

Induction heating uses alternating current to generate a varying magnetic field, which in turn induces eddy currents that heat the metal workpiece. The basic working principle is illustrated in Figure 1, where A represents the induction coil (also known as the load coil), and B is the metal workpiece being heated. When an alternating current flows through coil A, I 1 , then a time-varying magnetic field is generated within coil A, causing an induced electromotive force to be generated in workpiece B, which is placed in the alternating magnetic field. e 2 , forming a vortex I 2 These eddy currents cause the metal workpiece to heat up, consuming electrical energy. As shown above, induction heating relies on an induction coil to transfer electrical energy to the metal workpiece being heated, which then converts this energy into thermal energy internally. Notably, the induction coil does not make direct electrical contact with the heated metal—instead, energy is transferred via electromagnetic induction.

Basic Principle Diagram of Induction Heating

In induction heating, there are three effects—skin effect, proximity effect, and eddy current effect.

Skin Effect: When an alternating current flows through a conductor, the current distribution across the conductor's cross-section is uneven, with the highest current density occurring in the surface layer of the conductor. This phenomenon, where the current tends to concentrate near the surface, is known as the skin effect.

The proximity effect—when two conductors carrying alternating current are placed very close to each other, their currents redistribute due to mutual interaction. Specifically, if the currents in the two conductors flow in opposite directions, the maximum current density appears on the inner sides of the conductors; whereas if the currents flow in the same direction, the highest current density occurs on the outer sides of the conductors. This phenomenon is known as the proximity effect.

The "ring effect": When alternating current is passed through a ring-shaped coil, the maximum current density occurs on the inner side of the coil's conductor. This phenomenon is known as the ring effect.

Induction heating, on the other hand, comprehensively utilizes these three effects. A metal workpiece is placed inside the induction coil, and an alternating voltage is applied across the coil's terminals, generating an alternating current I. 1 , inducing an electric current I within the workpiece 2 These two currents flow in opposite directions, a situation similar to that of two parallel busbars carrying currents moving in opposite directions. When the current I 1 And induced current I 2 When coils and workpieces draw closer to each other, they exhibit the proximity effect, resulting in current I. 1 The current I gathers on the inner surface of the coil. 2 They gather on the outer surface of the workpiece. At this point, the coil itself exhibits the ring effect, while the workpiece itself demonstrates the skin effect.

Xi'an Aobang Technology Co., Ltd. is one of the early domestic manufacturers that have scaled up production of medium-frequency furnaces. Its main products include a full range of induction heating equipment, such as medium-frequency power supplies, IGBT power supplies, melting furnaces, and heating furnaces. For many years Focusing on Induction heating equipment Research and Development & Manufacturing Based in the ancient city of Xi'an, Aobang Technology is committed to "driving innovation in industrial heating through technology." Leveraging its core technologies accumulated from early large-scale production, the company provides customers with end-to-end services—ranging from equipment selection and installation/commissioning to process optimization.

The ancient city welcomes guests, together sharing the bonds of Aobang. We look forward to collaborating with more industry partners to push the boundaries of induction heating technology innovation. 13891865812 Mr. Luo

Previous

Next

Previous

Next

I want to consult