Product Details

Copper busbar

All the copper busbars in the cabinet are made of T2 or higher materials produced by first-line brands such as Luoyang Copper. The thickness of the busbar is ≥5mm, and the current flow per square millimeter of the copper busbar does not exceed 1.5A. (The copper busbar is strictly installed in accordance with national regulations and is equipped with fixed hangers and protective sleeves according to specifications). The large cross-sectional area copper busbar, which is higher than the national standard, has a lower current density per unit area of the connecting copper busbar than the same industry, which makes the heating of the copper busbar lower, and also achieves the purpose of energy saving. Because the heating of the copper busbar is lower, we do not need to weld water-cooled pipes on the ordinary connecting copper busbar in the cabinet, which makes the cabinet more concise, reduces water leakage points, and reduces the failure rate of the equipment. Its direction and connection have been subjected to electromagnetic simulation calculations during design to reduce the heat generation during equipment operation. All of these provide a strong guarantee for the reliable and stable operation of the intermediate frequency power supply.

In order to reduce the electrochemical corrosion of copper busbars in long-term use, all copper busbars in our company's cabinets are treated with international first-class processing technology. Long-term use practice has proved that the performance of the copper busbars treated by this process will not be attenuated.

Copper busbar treatment process in the cabinet: Sandblasting → Pickling → Passivation → Insulation encapsulation.

Slot copper busbar treatment process: Sandblasting → Pickling → Passivation → Insulation encapsulation → Resin spraying.

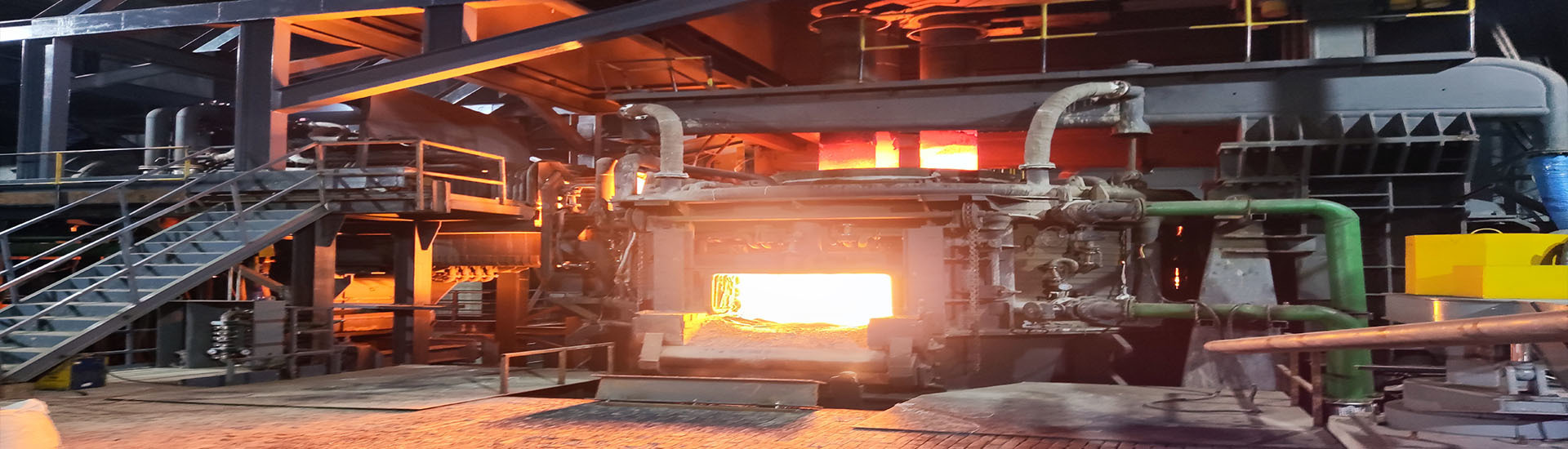

Xi'an Aobang Technology Co., Ltd. is one of the earliest manufacturers in China to produce intermediate frequency furnaces on a large scale. Its main products include a full range of induction heating equipment such as intermediate frequency power supplies, IGBT power supplies, melting furnaces, and heating furnaces. Long-term Focus on Induction heating equipment R&D and manufacturing , based in the ancient city of Xi'an, Aobang Technology takes "technology-driven industrial heating innovation" as its mission, and relies on the core technology accumulated in the early large-scale production to provide customers with a full-cycle service from equipment selection, installation and commissioning to process optimization.

Guests are welcomed in the ancient city to talk about Aobang's friendship Looking forward to working with more industry partners to expand the innovative boundaries of induction heating technology. 13891865812 罗总

Previous

Next

Previous

Next

I want to consult